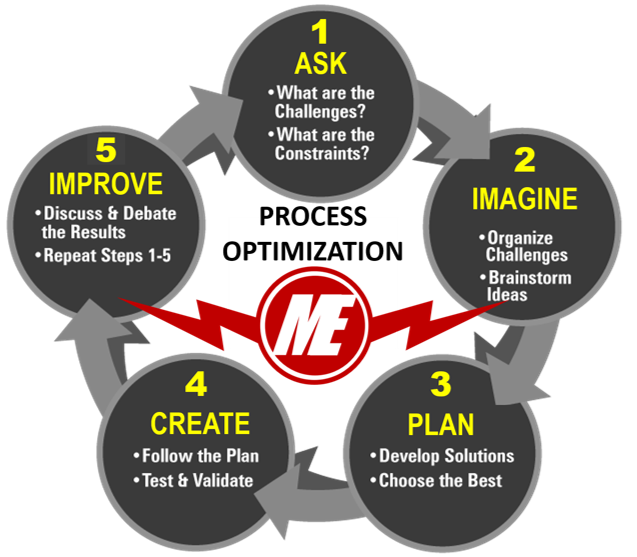

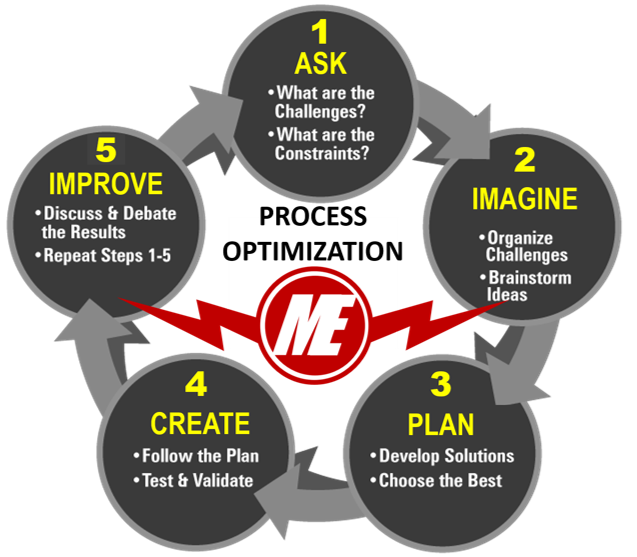

Maynard Steel Casting Company is constantly being challenged by its customers to deliver high-quality, smarter, and stronger solutions, quicker and more cost-effectively to market. We have the foundry capabilities, intellectual expertise, and experience to meet the constantly changing commercial needs of our customers. One part of this is our unique and collaborative 5PO Design Process.

Engineering Excellence

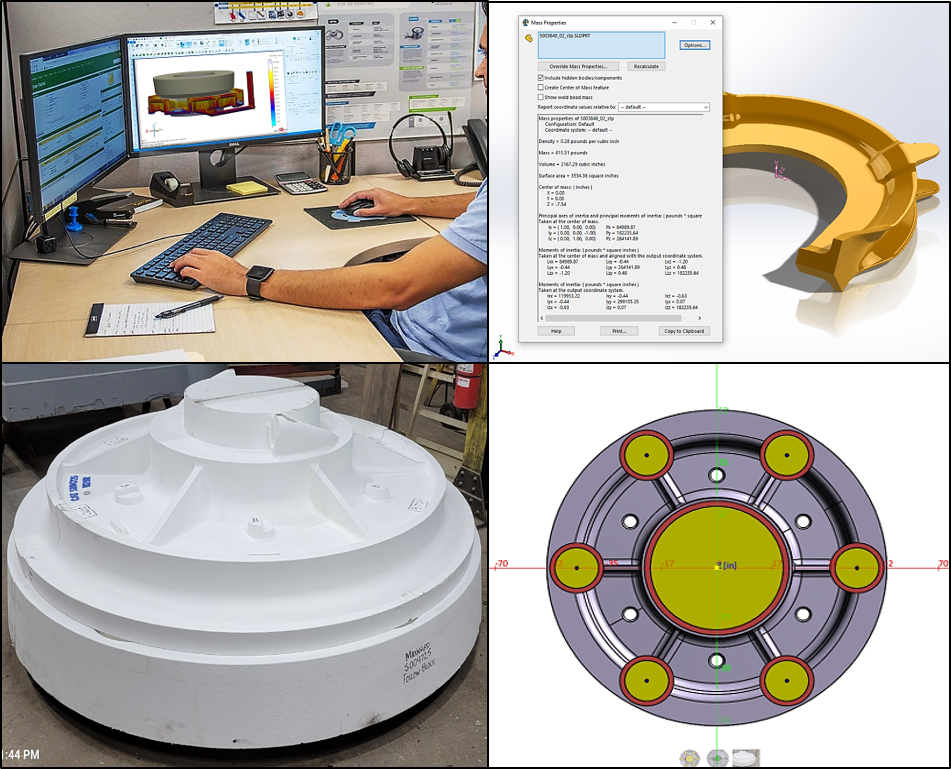

At Maynard Steel Casting Company, our product optimization and Design For Manufacturing (DFM) engineering capabilities are integral to our comprehensive "Full Service" business model. Our expert in-house technical team collaborates closely with customers, offering innovative expertise and personalized assistance. Equipped with advanced 3D Computer-Aided Design (CAD) tools, our engineers excel in solid modeling and casting simulations, ensuring the efficient production of high-quality low-carbon steel castings.

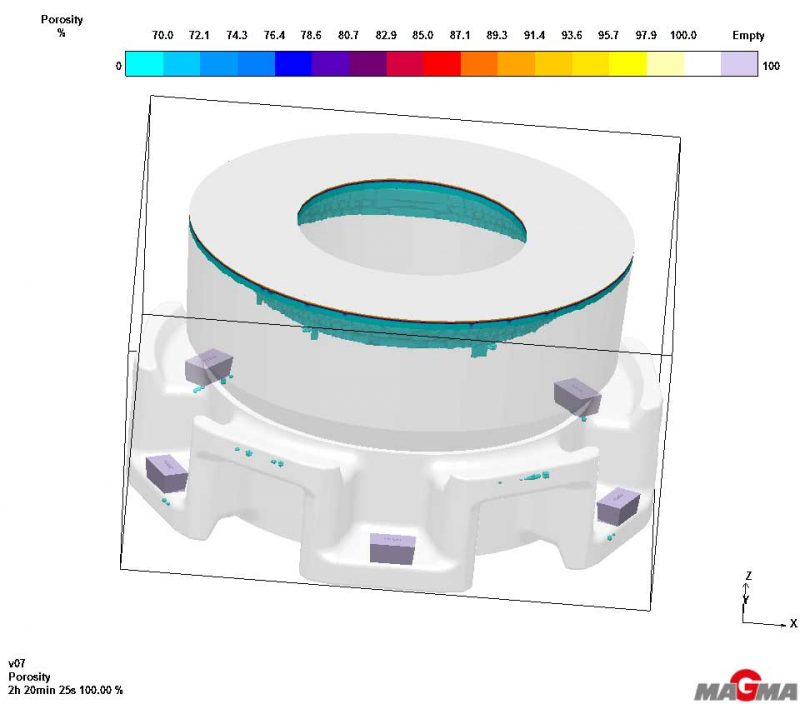

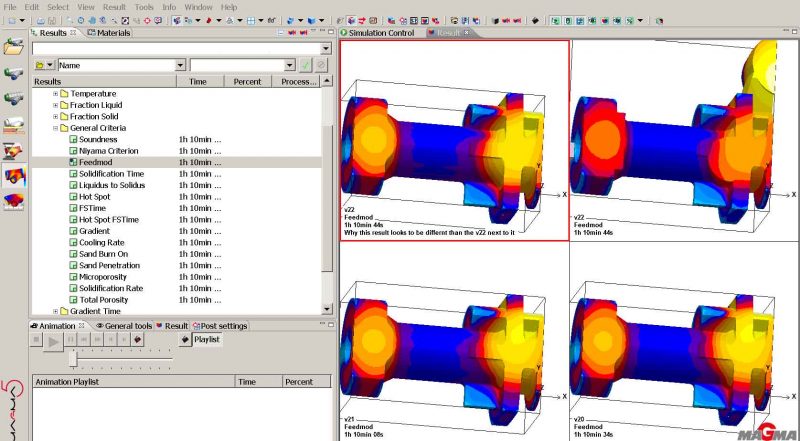

We utilize industry-leading software, including AutoCAD™, SOLIDWORKS®, and Pro/ENGINEER™, for strength modeling, and Magmasoft® for solidification simulations. We accept a variety of file formats such as PDF, HTML, GIF, TIFF, JPEG, DWG, DXF, and BMP via high-speed internet or email. For customers requiring assistance with Finite Element Analysis (FEA), we integrate the support of qualified outsourced engineering partners.

These methodologies enable us to perform value analysis, helping customers transition from costly fabrications or component assemblies to streamlined cast steel solutions. Our approach not only reduces costs but also decreases weight, simplifies manufacturing processes, and enhances overall product quality, performance, and reliability.

Our pattern services ensure design optimization, maintenance, and repair of foundry tooling while facilitating precise engineering adjustments. Most modern tooling is designed to our stringent specifications in partnership with trusted external pattern shops.

Additionally, Maynard’s expertise includes the use of Styrofoam designs in the casting process. A cost-effective solution for unique, custom applications. Whether utilizing customer-provided Styrofoam tooling or sourcing it from qualified and licensed vendors, we deliver innovative and efficient casting solutions.